Resilient Strength within Soft and Fluffy Comfort—The History and Appeal of Towel made in Imabari Vol.1 IKEUCHI ORGANIC

“When the Setouchi Shimanami Expressway is completed, people will come to Imabari, so we will sell towels here.”

Opened in 1999, the Setouchi Shimanami Expressway extends 60km from Imabari City in Ehime Prefecture to Onomichi City in Hiroshima Prefecture, passing through six islands in the Seto Inland Sea via bridges. Because of its splendid scenic beauty, the area attracts many tourists including cyclists.

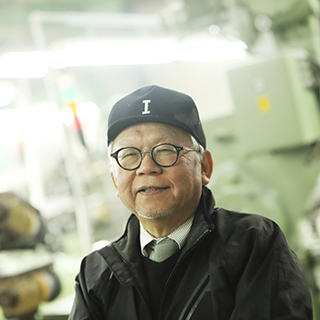

In the 1990s, Imabari, one of Japan’s leading towel production sites, was losing ground to imports. Mr. Keishi Ikeuchi, a representative and former president of IKEUCHI ORGANIC, was an official of the Shikoku Towel Industrial Association at that time. He continuously encouraged other producers, insisting that “when the Setouchi Shimanami Expressway is open, Imabari will be revived.” Imabari towels are now fully established as a high-quality towel brand. What kind of effort did the Imabari towel producers make to recover from the severe recession? This article also introduces the history of IKEUCHI ORGANIC, which has been challenging itself at the cutting edge.

From a Textile Production Site to a Towel Production Site

Today, about 20% of the towels in Japan are domestically-produced and about 80% are imported. Of the 20% of domestic production, about 60% are produced in Imabari and about 40% are produced in Senshu (southern Osaka).

It has only been about 170 years since the invention of the towel in the world. An importer from Osaka introduced it to Japan in 1872, and towel production started around 1887. Towels quickly gained popularity, and now Imabari and Senshu are the main production sites.

Imabari became a towel production site. It seems like it had something to do with cotton textiles.

Imabari had been a textile production site since the Edo Period. Entering the Meiji Period, less expensive imported cotton caused local cotton production to stagnate in the area, but the textile industry continued. Former producers of flannel (woolen textiles) in Imabari began making towels, and so Imabari became a towel production site.

Imabari had grown as a towel production site. However, beginning around 1990, production began to deteriorate due to the increase of low-cost imports, and towel factories closed down one by one. Imabari’s challenge of a resurrection began around 2000.

Around 2001, the towel manufacturers kontex and FUJITAKA, along with our company, opened a store in Shirokane, Tokyo. At that time, the Mayor of Imabari said, “Imabari City needs to do something since our private companies are toiling,” and a collaborative shop between the Towel Association and the city was opened in Ginza in 2003. However, skyrocketing land prices in Ginza right after its opening made it difficult to maintain the business, resulting in closure of the store after three years. After that, as a new initiative, our local organization registered the trademarks of “Imabari Towel” and the “Imabari Towel Brand Mark.” They gained popularity and promoted recognition of the Imabari towel brand.

Around the time when local brands began to be accepted by the public, an era started where the company’s own brand products (such as IKEUCHI ORGANIC) gained in popularity, Mr. Ikeuchi said.

We used to manufacture many licensed brand OEM (original equipment manufacturer) products for many years. Profits from this enabled us in 1999 to flexibly develop our concepts earlier than anyone else.

Listening to the Voice of the Customer. The Representative Personally Checks Email from Customers

The company was founded as Ikeuchi Towel Factory in 1953, producing its own products instead of licensed brand products. In the early 1970s, licensed towels for foreign-made luxury brands appeared and the company shifted to OEM production.

With the opening of the Setouchi Shimanami Expressway in 1999, for the first time we launched our own brand “IKT.” We didn’t yet have a clear vision at that time, but I thought that an age of organic would come soon.

Your company created its own brand and also developed an attentive system for customer feedback.

Our company website was made in 1995. With my email address as a contact address, I receive every inquiry from the customers. I still check emails from customers today. Before I joined my family business, I had worked for the audio brand “Technics” at Matsushita Electric Industrial (now Panasonic). A senior worker who trained me was the best marketer. My first job after joining the company was to check all the customer feedback cards. I was taught unequivocally to value the consumer perspective.

You left Matsushita Electric Industrial on December 20, 1982. You had originally planned to join Ikeuchi Towel Factory in February of the following year, at the 30th anniversary of its founding. Due to the sudden death of the former president a few days previously, you started working as president earlier than expected.

Since I was completely new to towel making, I eagerly studied everything about it. In two years, I developed a system for designing towels. All other manufacturers at that time were still manually operated. In order to differentiate us from other companies, I wanted us to be able to design on our own. I also wanted to establish our own brand with sophisticated quality, so our products would be cherished by consumers for a long time. Unfortunately, when we first launched our brand, there was no response at all. We thought our organic products might be more appealing to American consumers, and participated in an exhibition in the U.S. We focused on organic quality and intricate designs that utilized the best of Imabari’s textile techniques, but this also failed. To our surprise, the towels with simple designs were the most highly appreciated.

Your company went to New York in 2002, exhibiting for the first time at the New York Home Textiles Show, one of the largest textile exhibitions in the U. S., and won the Best New Product Award.

Our products had colors that could not be found in American towels, and we received a comment that “Ikeuchi’s colors are happy colors.” Our factories were already 100% operated by wind power, focusing on eco-friendly production processes, and this also accounted for our success.

A craftswoman fixing broken threads. Based on a flashing indicator light, she finds a broken thread among as many as 4000 threads and fixes it. She passed an internal examination by the Imabari Towel Industrial Association this year, becoming one of only a few women who have passed the exam.

Each product is visually checked at the final inspection. Bath towels are collaboratively checked by two people. Each thread that protrudes during the manufacturing process is cut by thread cutting scissors into a uniform length. “The high inspection quality is proof of the quality of the towel manufacturers.”

The entire process, from sowing cotton seeds in the field to the final product, can be seen by scanning the QR code. Most products shipped after December 2019 are equipped with this QR code. “We are the only towel producer in the world that provides traceability for towels,” said Mr. Ikeuchi.

We Might Head Somewhere Totally Unexpected as Soon as You Take Your Eyes Off of Us—The Challenging Spirit Attracts Fans

On February 11, 2013, Ikeuchi Towel Factory celebrated its 60th anniversary. Mr. Ikeuchi decided to rebrand it for the next 60 years.

At that time, our brand name in the U. S. was “IKT,” whereas in Japan, it was called “Ikeuchi Towel” or “Wind Woven Towel” because our products were manufactured by wind power. I wanted to unify these three. We solicited Mr. Kenmei Nagaoka, who works for D & DEPARTMENT PROJECT, for the rebranding. The only condition I gave him was the removal of the name “Ikeuchi.” Nevertheless, Mr. Nagaoka proposed “IKEUCHI ORGANIC.” At first, I couldn’t understand why “Ikeuchi” remained, in spite of my only condition (laughs). Mr. Nagaoka said, “I’ve researched a lot about organics, but your company’s idea is different from others—it’s Ikeuchi-style organic.” Our logo is yellow, which is uncommon for organic manufacturers, but this also constitutes the uniqueness of IKEUCHI ORGANIC.

On March 1, 2014, Ikeuchi Towel Factory was reborn as IKEUCHI ORGANIC. At the same time, our company obtained Class I certification to the STANDARD 100 by OEKO-TEX, which certifies that all of our products are free of any harmful substances.

Furthermore, the company sets a mission to make a towel that is edible by babies by 2073 (the company’s 120th anniversary). What do you mean by edible towels?

Since we were participating in an exhibition in New York in February 2014, we held a party prior to that in Japan to celebrate our company’s new name. I thought we needed a joke since it was an American party, so I said, “Next, we’ll try to develop a towel that is edible by babies,” and then people unexpectedly loved it. So that’s how it was set as our corporate mission (laughs). But this further clarified our direction. In order to elevate the level of safety, we obtained ISO 22000 certification for the food industry. Naturally, we thought traceability was also necessary.

After launching the company’s own brand “IKT” in 1999, it established the concept of “maximum safety and minimal environmental impact.” Its safety level is increasing year by year.

I don’t think we have fully satisfied our customers just yet. Our customers remain fans because our concept continuously develops. We might head somewhere totally unexpected as soon as you take your eyes off us. We’ll keep transforming like that. A towel that is edible for babies may still be a joke right now. However, there is a good chance that we might live in an era in 60 years where clothing can be swallowed without causing any harm.

I heard your company also increasingly has more field trips for elementary and middle school.

This year, I told a field trip participant, “Please come back after 60 years to see if this old man lied to you (laughs).” Then the student said, “No problem, I’ll join your company and work properly for it.” I was happiest this year to hear that.

Mr. Ikeuchi said, “Wiping your face with a towel that’s very soft to the touch, after waking up in the morning, makes you feel good for the rest of the day. A towel can change a person’s life.”

About 20 years have passed since experiencing the decline of the towel industry in Imabari. Today, Imabari’s towel manufacturers, including IKEUCHI ORGANIC, are proud of their towel production, resulting in revival of the industry. Imabari’s towels will reach more people and softly wrap their daily lives. I was able to clearly envision the future of IKEUCHI ORGANIC, which continues to create exceptionally unique products and attract many fans.

TEL: +81-898-31-2255

https://www.ikeuchi.org/

https://www.facebook.com/ikeuchi.org/

https://www.instagram.com/ikeuchiorganic/

https://note.com/ikeuchiorganic